台湾钢铁业龙头,年产能高达1,600万吨,面对全球ESG风潮积极迈向零碳制程。为达成目标,客户决定使用新代集团的联达机械手臂与正铂雷射打标机台,从每个钢卷的生产标示入手,着手改进生产过程中打标流程。在不影响产能和质量稳定的前提下,引入了六轴机械手臂,打破了大型钢卷雷射打标的技术瓶颈。

传统方式中,客户为避免混料问题,需在钢卷外圈手工书写或油墨喷印号码;然而,这不仅带来了墨水耗材、定期维修以及油墨难以清除的问题,更甚的是,由于无法提供清晰的钢卷表面,客户端通常需要切除有号码区域的钢卷带,导致客户材料损失,也提高了整体购料成本。

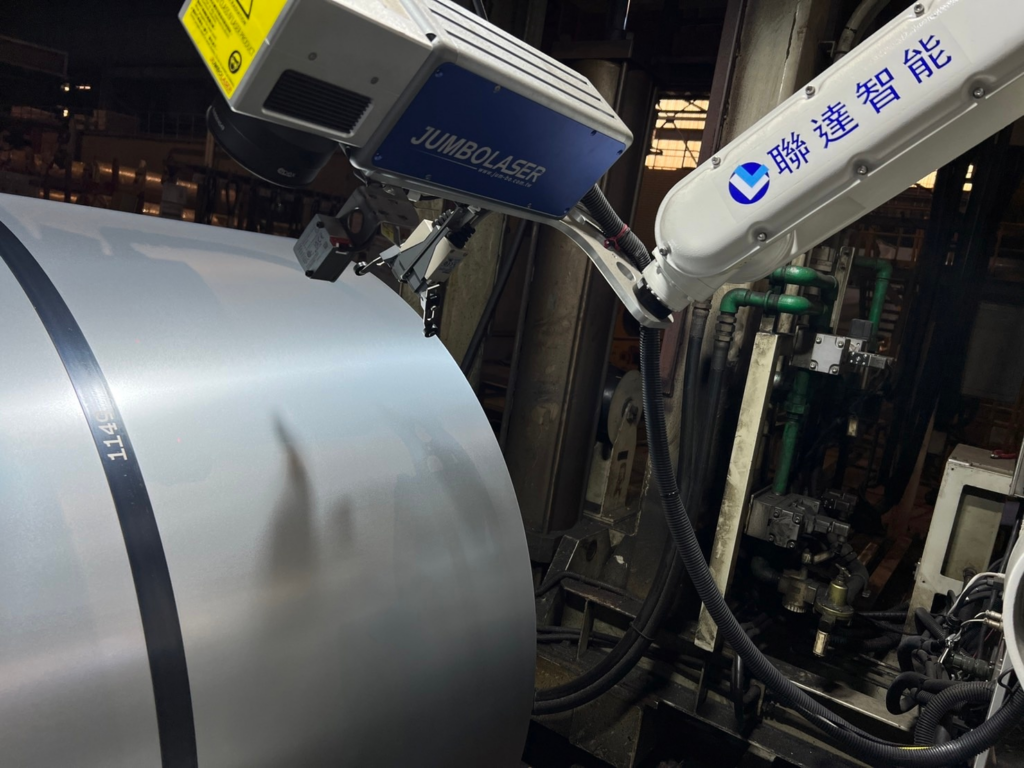

在与新代集团旗下的正铂雷射与联达智能团队的合作之后,企业导入联达C系列六轴机械手臂 ,整合搭配雷射打标系统、影像摄影机、AI影像辨识系统和雷射测距仪等智慧定位系统,提供行业工艺包并实现钢卷号码精准打标。手臂搭配视觉做自动定位,可灵活适应不同的钢卷尺寸,达成弹性生产。机器内部搭载的新代科技控制器,具备简易上手的编程对话编程并提供三大客制工具平台,满足使用者在不同情境的应用需求。雷射打标具有速度快、功率稳定、使用生命周期长的优势,完美解决了钢卷材料耗损和环境污染问题。联达手臂搭配新代控制器具有高度整合的优势,从路径规画、对位补偿到工业通讯皆有相对应方案,大幅缩短自动化应用的整合开发时程。以联达手臂为主体的解决方案,搭配多元加值方案,将工厂智慧转型的门槛降低,协助客户无痛升级。

透过采用新代集团旗下的联达智能和正铂雷射的先进技术,我们提供客户全面的智慧自动化解决方案和相应的行业工艺包。凭借新代集团一站式购足的模式,工厂转型无需繁琐的多方协调!机械手臂导入生产流程以及雷射打标标示钢卷号码,不仅消除了对环境的污染,同时解决了公司钢卷耗料的问题。这项技术的成功应用,每年帮助企业节省近千万元,实现制程零污染、降低浪费、降低成本的目标。

推荐产品:

联达C系列六轴机械手臂

参考文案: 【正铂雷射成功案例】提升得料率,年省近千万元