客户背景

盟英科技专精于谐波减速机的研发、设计及制造,并通过ISO9001质量认证,深得客户信任。除了挹注强大的研发能量,取得多项专利认证,盟英也在先进的加工工艺上投入大量资源,确保优良的质量与生产效率。

▲ 盟英谐波减速机及其关键零组件

客户痛点

然而,生产与质量管理所面临的挑战,也随着追求更标准产品的同时日益严峻。

内部面临生产状况、产能不透明,以及报工不实时造成的信息落差,加上缺乏系统性的整合信息;外部则遭遇临时抽插单情况要应变,导致排程混乱无所依据。此外,厂内生产半成品、成品、委外工件等皆有序号需求,维护上无法整合进行追踪,且无法单凭序号辨识及区分产品。

而在数据为王的质量管理面向上,过往多依赖手动量测产品数据,再透过纸本抄写,人工输入系统,且检验仪器多元,不同仪器汇出档案格式不同,要进行数据分析相当耗时费力。且机边量测皆为人工填写纸本记录检验数据,再手动计算检验结果,亦有误判情形发生。

克服挑战

联达SynFactory生产管理模块及品检管理模块,专为金属加工行业打造,以不同工厂管理需求角度出发,模块功能全面,设计弹性可依据不同使用情境调整。在此案中,联达以顾问角色,偕同客户梳理生产流程上的痛点并排定优先级,进行阶段性导入,协助盟英快速实现智慧工厂愿景。

项目效益

1. 减少人工对照生产进度时间80%:系统提供实时稼动率、生产进度,让生管人员可以准确推估排程。

2. 工单填写及回报时间缩短95%:系统整合工艺信息可快速套用至工单中

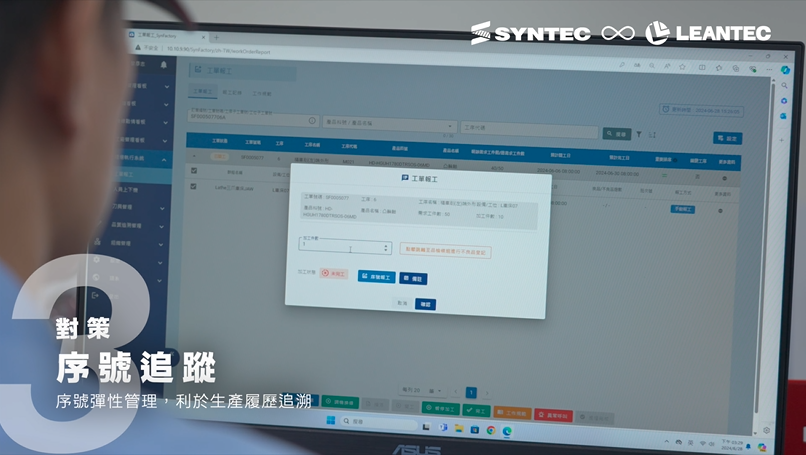

3. 序号追踪:提供多样序号规则制定功能,结合BOM组合序号产生母子关系,便于后续产品生产、质量等状况等追踪。

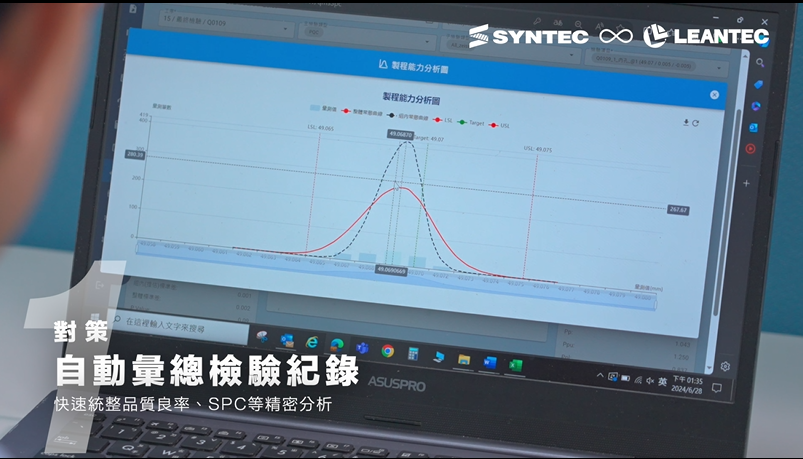

4. 自动汇总检验纪录:快速统整SPC、质量良率等精密分析数据,减少人力重复汇整资料与分析的时间。

5. 量测数据数字化:快速自动判别该站检测结果,避免人为误判情形发生。

联达生产智慧云透过整合OT段到IT段信息,达成掌握产线实时信息及强化质量管理的目标,赋能制造业自动化、畅流与数据化的能力,全面强化制造韧性。

关注联达公众号,最新消息&咨询不错过