LEANTEC

LEANTEC  2160

2160

There are pain points in traditional robot loading and unloading, such as large space occupation, hard to changeover and long turning time. Leantec has launched a mobile robot trolley solution for machine tool loading and unloading, realizing the vision of continuous production.

High-mix and low-volume production has become the norm in manufacturing, and the introduction of robotic arms has become an indispensable key element for factory production. However, traditional robotic arms occupy a large area, difficult to changeover, and take a long time to tune and other pain points, which discourages factory owners. In order to solve the pain points of traditional arm automation, Leantec has launched a mobile robot trolley solution for machine tool loading and unloading. This solution is equipped with standard configuration, such as robotic arm, mobile trolley, and tray silo module, and suitable for small quantities and diverse metal processing industries.

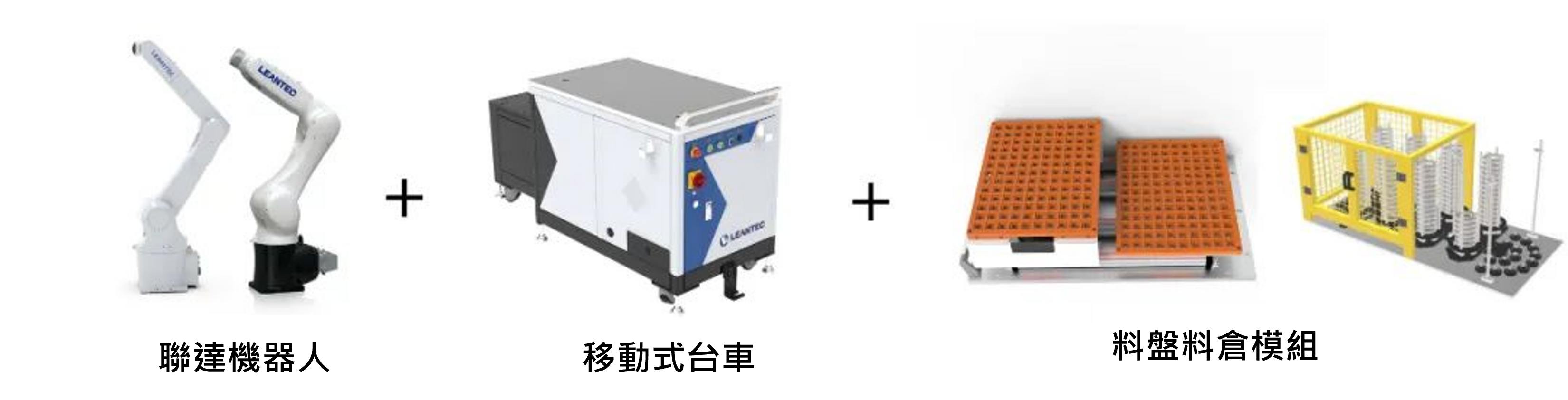

Configuration

Standard configuration: Leantec robot + mobile trolley + tray and silo module

· Leantec Robot: The machine tool loading and unloading robot mobile trolley can be equipped with Leantec Y series 917 arm span and R series 1206 arm span;

· Mobile trolley: The overall dimension of the trolley is 1650*600mm with casters at the bottom. The whole unit adopts a stepped structure design to reduce the interference factor of pick-and-place. With a dense arm installation foundation, leaving room for workers to change tools and operate the machine tool panel;

· Tray Silo Solution: The silo solution can adopt the double-layer automatic feeding tray or the rotary silo.

Optional configuration: Material tray, rotary table, positioning table, and fixture

· Material tray: Be used as a storage and auxiliary positioning. In this solution, the default size of a single tray is 550 x 420 (mm). The size of the tray can also be customized according to customer needs;

· Rotary table: Be used as the function of turning workpieces, and is mainly composed of a turning cylinder, a 2-finger gripper cylinder and a magnetic switch, which can also be customized according to requirements;

· Positioning Table: Be used as auxiliary positioning. When encountering a special workpiece, the robot is positioned by the positioning table, and the workpiece is placed at a fixed angle, which can also be customized according to requirements;

Fixture: The fixture is optional, and adopts the traditional pneumatic double jaw design. The arm body has a built-in air tube and IO wire for easy air routing.

Advantage

1 Flexible movement and Quick Installation

Designed in the mobility, which can be moved flexibly. The bottom is equipped with casters and L-shaped fixed brackets, which is convenient for installation and fixation and secondary repeated positioning.

2 Fast Machine Tool Communication

When integrated with the Syntec machine tool system, only one network cable can realize communication with the machine tool; when integrated with other brand machine tools, the IO aviation docking plug is used for quick connection.

3 Simple Tuning, Quick Production

It only needs to test the communication signal and teach the pick-and-place point of the machine tool chuck, which saves on-site tuning time and can be put into production quickly.

4 Fast Changeover

According to the production plan, it is convenient and quick to transfer the machine, and realizes the production demand of changeover after simple tuning.

5 Continuous Production Generates Revenue Rapidly

During processing and production, there is no need to stop the arm and the machine tool, and raw workpieces can be added for processing under the premise of ensuring safety, realizing continuous production without stopping

Application

One customer's processing product is a hexagonal nut workpiece with angular positioning. It is matched with other brand machine tools for one-to-two double-process pick-and-place processing. In this case, it adopts Leantec's double-layer automatic tray mobile trolley solution: